Introduction

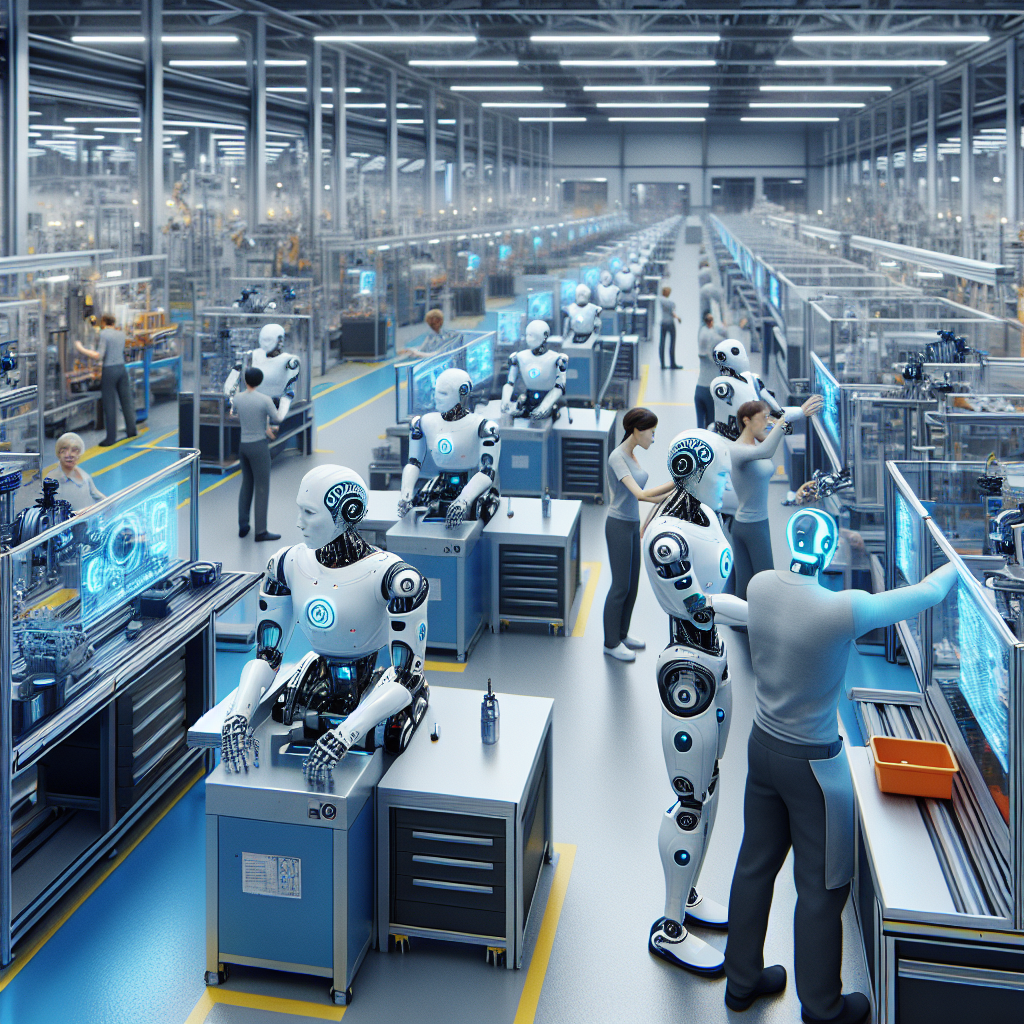

The manufacturing sector is witnessing a revolutionary change driven by robotics. As industries seek to enhance efficiency, reduce costs, and maintain high-quality standards, robots have emerged as a critical component in this evolution. This article delves into how robotics is shaping the future of manufacturing, exploring automation, the integration of artificial intelligence, and the implications for the workforce.

The Rise of Industrial Robotics

Industrial robotics refers to the use of robotic systems in manufacturing processes. These robots are designed to perform specific tasks, such as assembling components, welding, painting, and packaging. The rise of industrial robots can be attributed to several factors:

- Increased Efficiency: Robots can work tirelessly without breaks, thus enhancing production rates and efficiency.

- Precision and Consistency: Robotic systems provide high precision in tasks, which reduces errors and ensures consistent quality in manufactured products.

- Cost Reduction: Despite the initial investment, robots can help manufacturers save money in the long run by reducing labor costs and minimizing waste.

Automation: The Backbone of Modern Manufacturing

Automation involves the use of technology to perform tasks without human intervention. It is intrinsic to modern manufacturing and is facilitated largely by robotics. The benefits of automation include:

1. Streamlined Production Processes

Robotic systems can be programmed to perform multiple tasks, leading to streamlined workflows. For example, in a car manufacturing plant, robots can handle everything from stamping metal parts to assembling them into the final product. This seamless integration reduces downtime and boosts productivity.

2. Enhanced Safety

By deploying robots in hazardous environments, manufacturers can significantly improve workplace safety. Robots can handle dangerous materials and perform risky processes, reducing the likelihood of accidents and injuries among human workers.

3. Flexibility and Adaptability

Modern robots are increasingly equipped with artificial intelligence and machine learning capabilities, enabling them to adapt to changing tasks and production lines. This flexibility allows manufacturers to pivot quickly in response to market demands.

Artificial Intelligence: A Game Changer

The integration of artificial intelligence (AI) with robotics is poised to disrupt the manufacturing landscape further. AI-driven robots can analyze data in real-time, leading to smarter manufacturing processes. Here’s how AI is making an impact:

1. Predictive Maintenance

AI algorithms can monitor machinery performance and predict failures before they occur. This proactive approach minimizes downtime and maintenance costs, ensuring a smoother production process.

2. Quality Control

AI-enabled vision systems can inspect products for defects at a much faster rate than human workers. By detecting problems early in the production line, manufacturers can reduce waste and improve overall product quality.

3. Supply Chain Optimization

Using AI in conjunction with robotics can enhance supply chain efficiency. AI can analyze market trends and predict demand, making it possible to automate inventory management and distribution processes effectively.

The Future Workforce: Humans and Robots Collaborating

While robotics and automation are transforming manufacturing, concerns about job displacement due to increased automation are prevalent. However, rather than fully replacing human workers, the future of manufacturing will likely be characterized by collaboration between humans and robots.

1. Augmented Workforce

Robots will take over repetitive and dangerous tasks, allowing human workers to focus on more complex and creative roles. This shift can lead to higher job satisfaction and increased value within the workforce.

2. New Skill Requirements

As robotics becomes more integrated into manufacturing, there will be a rising demand for workers skilled in robotics, programming, and data analysis. Retraining programs and educational initiatives will be crucial to prepare the workforce for the changing industrial landscape.

Challenges and Considerations

Despite the numerous benefits of robotics in manufacturing, several challenges must be addressed:

1. High Initial Investment

The cost of purchasing, installing, and maintaining robotic systems can be substantial, posing a barrier for small and medium enterprises. However, as technology advances and becomes more accessible, these costs are expected to decrease.

2. Cybersecurity Risks

As manufacturing processes become increasingly digitized and connected, the risk of cyberattacks grows. Manufacturers need to invest in robust cybersecurity measures to protect their data and automated systems.

3. Ethical Concerns

The rise of robotics prompts ethical considerations, particularly regarding job displacement and privacy. Balancing technological advancement with ethical practices is essential for sustainable growth in the sector.

Conclusion

Robotics is undeniably shaping the future of manufacturing by driving efficiency, enhancing safety, and enabling smart production. As we look ahead, the successful integration of robotics in manufacturing will depend on collaboration between human workers and machines, alongside addressing the challenges that arise. Embracing this technological revolution can lead to a more innovative, efficient, and resilient manufacturing landscape.